-

-

- Rework Station

- Material Dispenser

- Dispensing System

- Laser Marking Workstation

- Automated Loading/Unloading Machine

- Cutting Machine

- Automated Optical Inspection (AOI) Machine

- Dispenser/Solder Paste/Pick-and-Place Smart Module

- PCBA Pre-Inspection Machine

- Oven Temperature Profiler

- Automatic Stencil Cleaning Machine

- Automatic Tool Cleaning Machine

- Multi-functional Cleaning Machine

- Automatic PCBA Cleaning Machine

- Scanning Acoustic Microscope (SAM)Sonoscan

- Automatic X-ray Inspection

- Cleaning Detergent

- PCB Laser Marking Machine

- Solder Paste

- Automatic Loader/Unloader

-

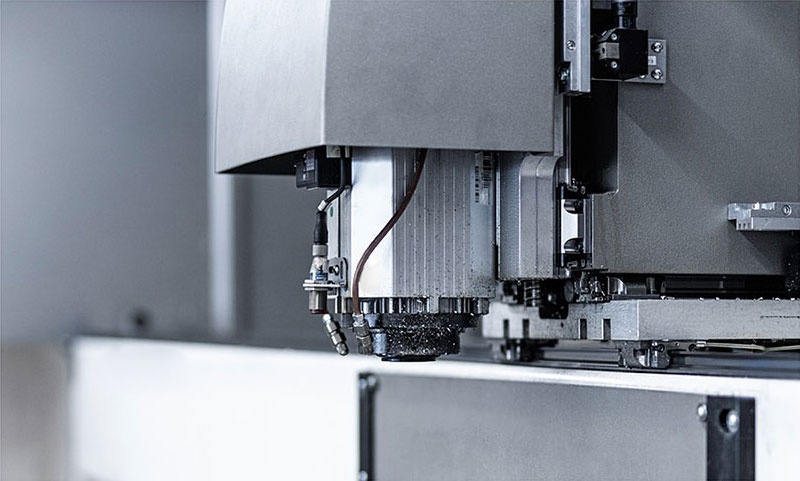

- Wafer Dicing Machine

- UV Curing Machine

- Automated Optical Inspection (AOI)

- Inline Vacuum Reflow Oven

- Contact Angle Meter

- 3D Non-Contact Profile Measurement System

- Temperature Control Equipment

- Lens Optical Transmittance Testing Machine

- Wafer Film and Tension Tester

- Atmospheric Plasma Cleaning Equipment

- Batch Plasma Treatment Equipment

- Wafer Plasma Treatment System

- Vacuum Plasma Treatment System

- High-Performance Surface Coating System

- Optical Inspection System

- X-ray Inspection

- Scanning Acoustic Microscope (SAM)

- Bond Tester

-

- Servo Motor Welding Head

- Parallel Seam Sealing System

- Resistance Welder

- Laser Cutting System

- TIG Micro Wire Welding Equipment

- Micro Laser Spot Welder

- Glove Box

- Ultrasonic Metal Welder

- CO2 Cleaning Machine

- UV Curing System

- Irradiator

- Leak Detector

- Cover Uncovering Machine

- Vertical Smart Storage System

- Horizontal Smart Storage System

-

-

-

-

Rework Station

Rework Station

.png)